High Precision Dental Ortho Model Resin for 3D Printing

Perfect for orthodontic labs

Easy to make any ortho models

Affordable and high quality

orthodontic model material

Our Ortho Model Resin is specifically formulated to produce high-precision, rigid, and dimensionally stable models. It is ideal for:

Orthodontic and dental models for diagnosis and treatment planning.

Study models

Crown and bridge models.

General purpose engineering and prototyping models requiring fine details.

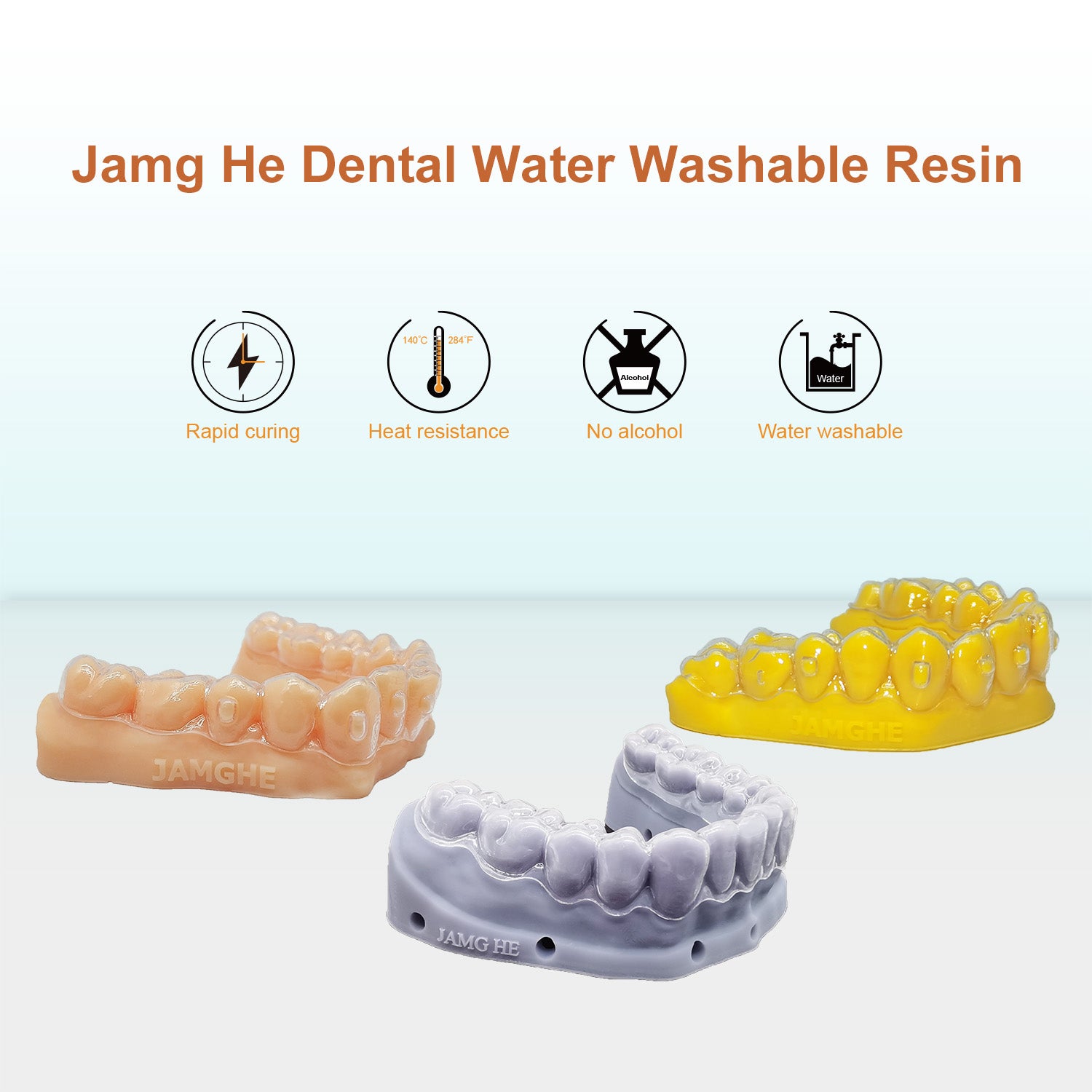

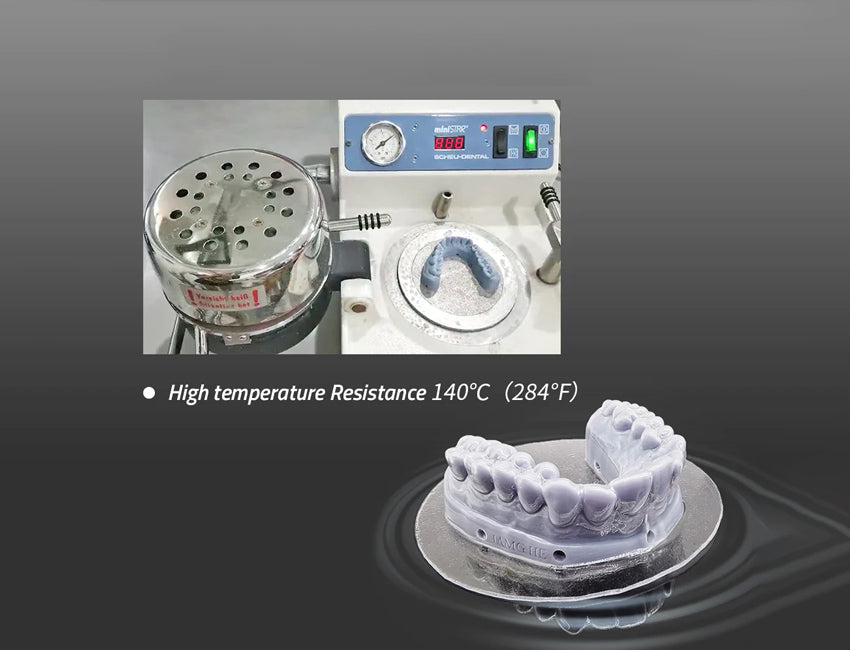

High Temperature Resistance

3D print resin mold Easy to make any orthodontic brace with vacuum forming machine.

No matter how thick of the thermal forming plastic sheet, and allow you to reuse the same model for a few times.

Low Shrinkage & Dimensional Stability

This dental 3d printing resin has excellent strength and stability performance, can reach the dimensionalaccuracy of ±30um and long-term retention, high strength, low shrinkage, Fast Printing with extremelyhigh storage stability. lt is suitable for mass production of dental implant and repair modelsto meet the efficient needs of clinics and technical institutes

Low odor & non crack

JAMG HE full range of 3D printing dental resins have a lower odor, making them safer for home studios, schools and offices. There are no harsh chemicals to cause headaches.In addition, the antioxidant formula of the resin makes the model's long-term dimensional stability >99.9%at room temperature and no moisture absorption and deformation under 60% humidity, avoiding the traditional plaster model cracking and chalking problems

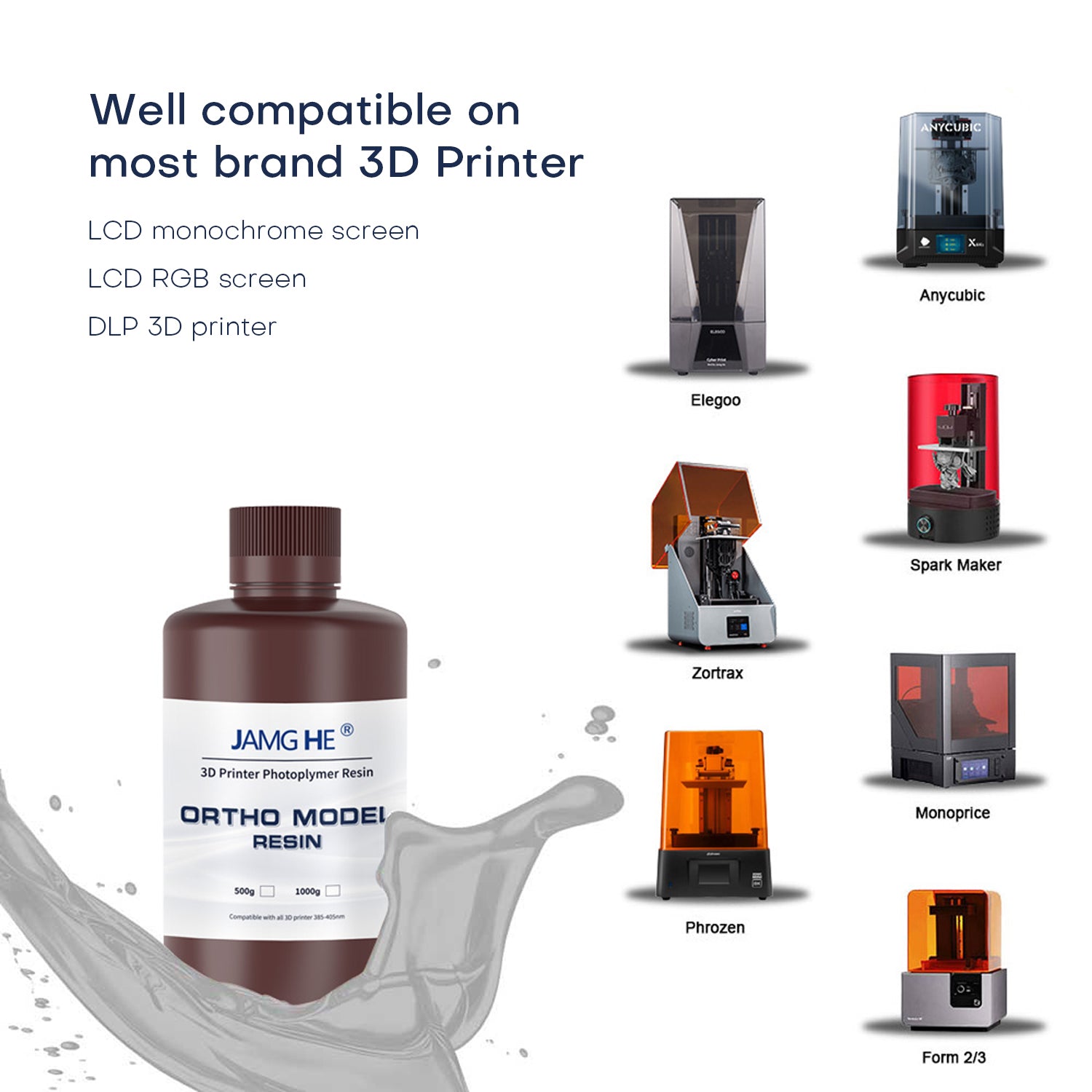

High Compatibility

Our professional research and testing team has extensively tested and optimized the performance of jamg he dental orthodontic model on various brands of printers to ensure excellent compatibility and ease of use. JAMG HE 3D printer resins are highly compatible with the majority of LCD and DLP 3D printers, so no matter if you're a beginner or an experienced user, our 3D printing resins will provide you with the perfect solution for your resin 3D printing needs and provide a seamless printing experience and excellent results

Have questions about our Ortho Model Resin? We're here to help. Find answers to our most frequently asked questions below. If you need more specific technical support, please contact our experts or request a bulk quote.

A: Our Ortho Model Resin is specifically formulated to produce high-precision, rigid, and dimensionally stable models. It is ideal for:

Orthodontic and dental models for diagnosis and treatment planning.

study moldels

Crown and bridge models.

General purpose engineering and prototyping models requiring fine details.

A: This resin offers an excellent balance of properties ideal for handling and clinical use:

Tensile strength (MPa):37.88 ±10%

Elongation at break (%):3.09±10%

Flexural modulus (MPa):1699.7±10%

Notched impact strength (J/m):72 ±10%

Hardness(Shore D):80-88D

viscosity (mPa·s):250-400

Density(g/cm³):1.05-1.25

For the most detailed and up-to-date technical information, please refer to our Technical Datasheet.

A: Our resin is designed for MSLA (LCD) & DLP 3D printers using a 405nm wavelength light source. This includes popular brands like:

Formlabs (Form 3/3B/3L)

Anycubic (Photon Series)

Elegoo (Mars, Saturn Series)

Phrozen (Sonic Mini, Shuffle Series)

And other similar LCD/DLP printers.

*Please note: It is NOT compatible with SLA laser-based printers (e.g., original Form 1/2) or FDM printers.*

A: Settings vary slightly by printer model. As a starting point, we recommend:

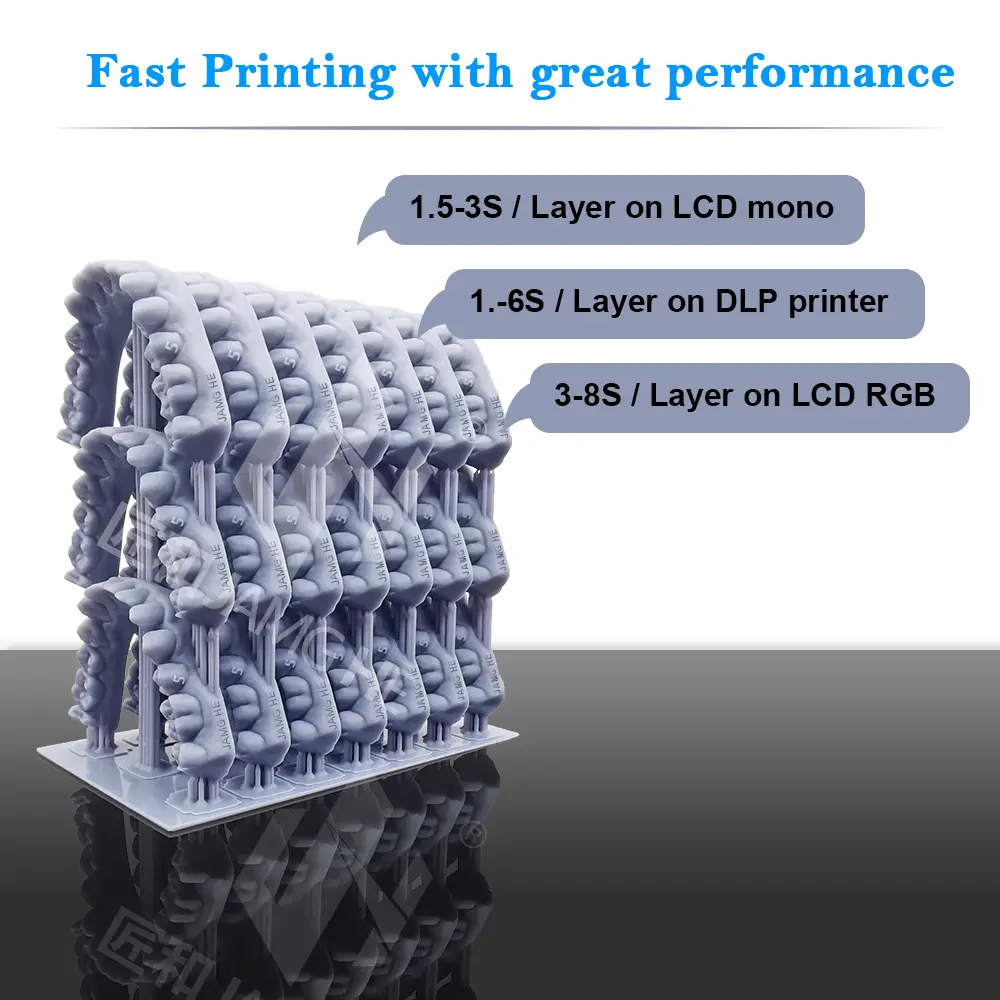

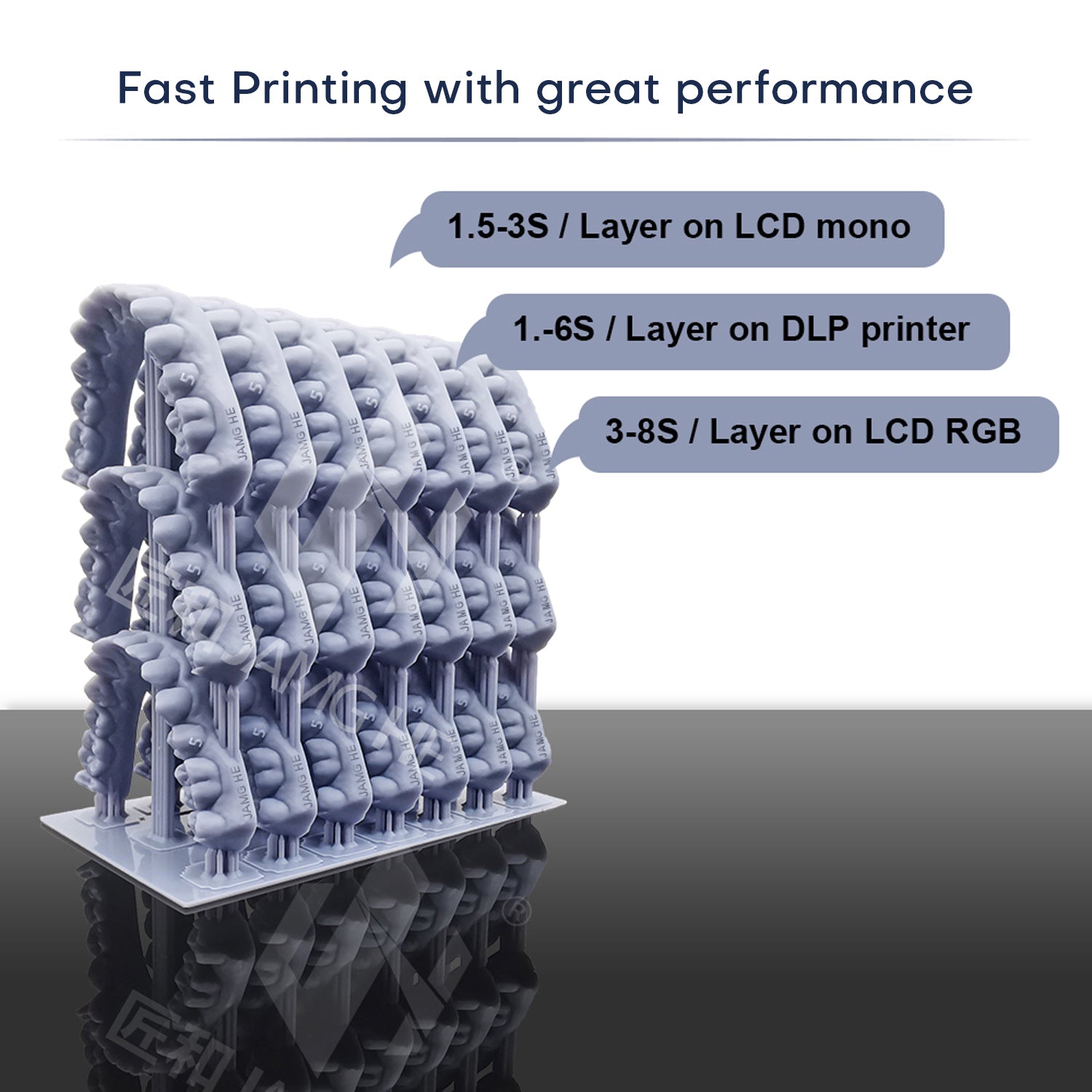

Rapid curing in all type DLP LCD 3D Printer

LCD mono : base exposure time 25-50s, normal exposure 1.5-3s

LCD RGB screen: base exposrue time 50-100s, normal exposure 3-8S

DLP printer : base exposrue time 15-20s, normal exposure 1.-6S

We provide a detailed Printer Profile Library with optimized settings for specific printers here.

A: Print failures are often due to incorrect settings. The most common fixes are:

Re-calibrate Exposure Times: Increase exposure time by 0.5-1 second increments if layers aren't bonding.

Level Your Build Plate: An unleveled plate is the #1 cause of print failures.

Check FEP Film: Ensure it is taut and clear of scratches or cloudiness.

Resin Temperature: Ensure your printing environment is between 25-30°C (77-86°F). Cold resin is viscous and prints poorly.

For a detailed troubleshooting guide, visit our Support Center.