High Wax Plus Resin

60% wax resin

Great performance

Smooth surface

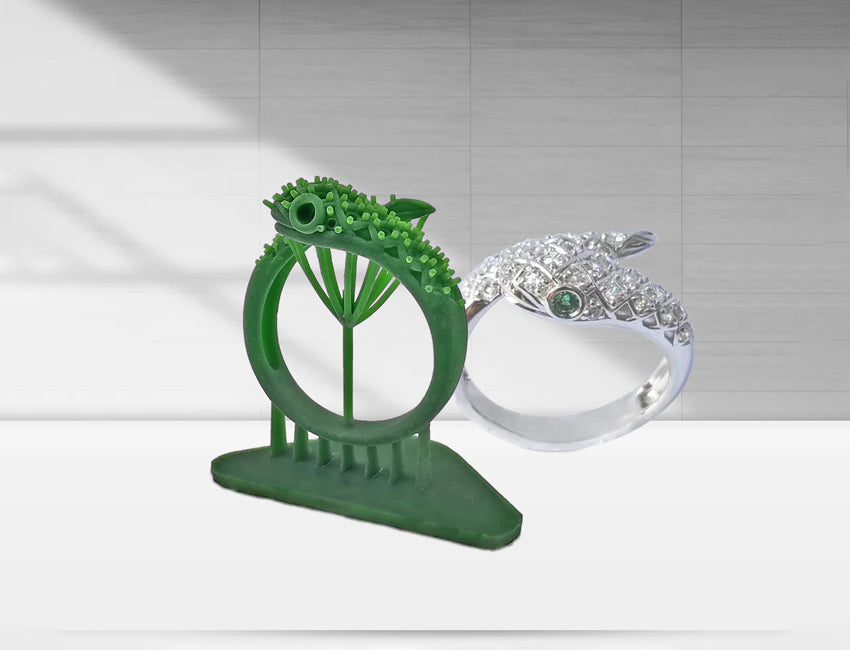

Suitable for filigree and diamond jewelry casting

High Wax Plus Resin

High wax plus 3d casting resin ewic-3000a is great option for jewelry casting, contains at least 60% wax.

Which is easy casting for any design jewelry, no matter is man ring or filigree ring.

Why Choose High Wax Plus Resin

- Easy to Cast

High Wax Plus Jewelry Resin supports a wide range of lost wax casting conditions and is compatible with leading gypsum investments.

- Design Flexibility

Create heavy jewelry and difficult-to-cast features with ease.jewelry casting resin will minimize common expansion related defects.

- 60% wax resin

60% high-wax formula improves mold flow for intricate filigree patterns, reducing bubbles and material waste by 30%.

- Great performance

Withstands burnout high temperatures and is compatible with all LCD/DLP 3D printers (405nm wavelength), ensuring consistent results for jewelry manufacturers.

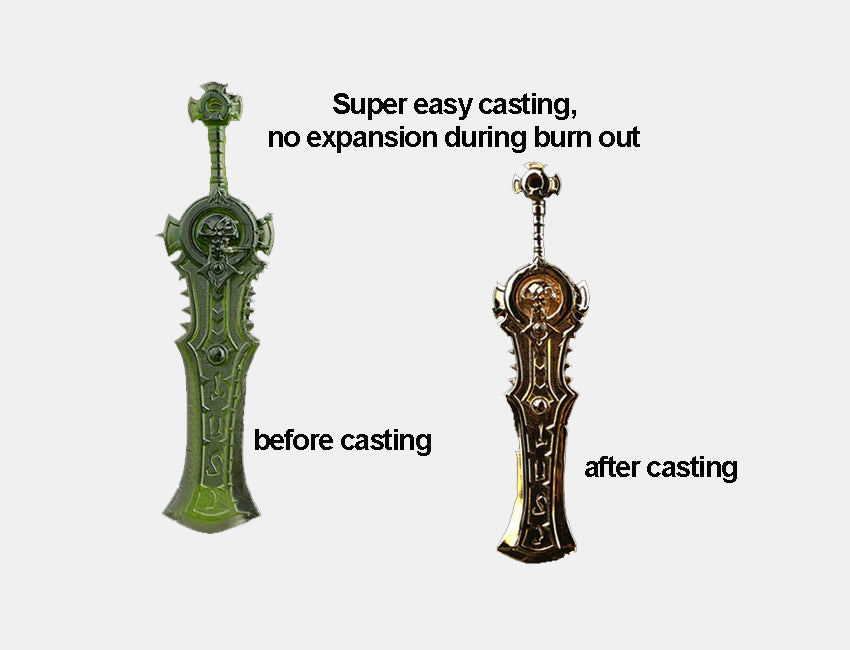

High Accurate Size

3D printing high wax plus resin 1:1 casting result, no expansion during burn out, so you will get accurate size jewelries after casting.

Applications

JAMG HE High Wax Plus Resin: 60% wax content, 1:1 casting accuracy, and smooth surfaces,Castable Wax Resin is ideal for lightweight, intricate jewelry or for prototypes and production.

- Delicate filigree designs

- Custom try-ons

- Direct investment casting

- Thin pieces with fine details

Viscosity (mPa·s )

150~230(mPa·s )(25℃)

Relative density (g/cm3)

1.05g/cm3

(25℃)

Auto-ignition temperature(℃)

>450

Download TDS

Download TDS( Click here)

Download SDS( Click here)

A: High Wax Plus is specifically formulated for lost-wax casting. Its key advantages are:

Ultra-Low Ash Content: Ensures a clean burnout, leaving zero ash residue that can cause imperfections in your final metal piece.

Optimized Thermal Properties: Minimizes expansion during the burnout cycle, preventing mold cracks and ensuring precise reproduction of fine details.

High Green Strength: Makes it easier to handle, sprue, and invest delicate patterns without breakage.

A: Yes! High Wax Plus Resin has been rigorously tested for compatibility with all major gypsum-based investment powders on the market, including brands like R&R, Prestige, and Kerr. It is designed to work reliably under a wide range of casting conditions.

A: High Wax Plus is a standard UV photopolymer resin. It is compatible with all LCD/MSLA 3D printers (using a 405nm wavelength UV source). We provide recommended printing parameters for common printer models on our support page and in the product documentation.

A: It achieves a 1:1 casting effect with no expansion during the burnout process. This ensures that the final jewelry products have precise dimensions after casting, meeting the requirements for high dimensional accuracy in jewelry production.

A: It is particularly suitable for delicate filigree-designed jewelry, custom try-on jewelry, and can also be used to make thin-walled jewelry pieces with fine details. Additionally, it is applicable for jewelry prototype production and mass production.